Can you guess the term that encapsulates this intricate phenomenon? That’s right—it’s the fascinating world of “Supply Chain.” It’s the backbone of every product you encounter, and biomass briquettes are no different.

Biomass Briquettes Supply Chain

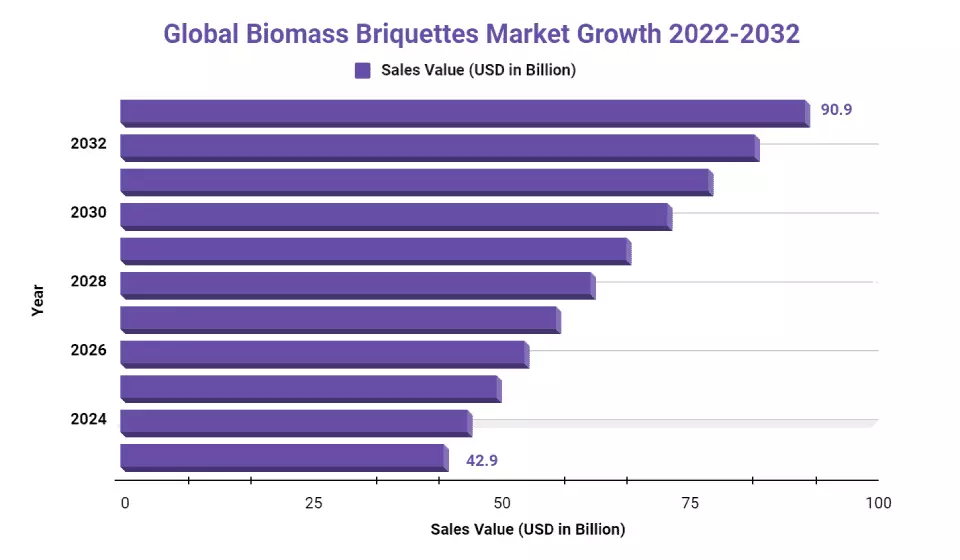

Source credit: Market.us

Key Components of an Efficient Biomass Briquette Supply Chain

1. Establishing a dependable supply of biomass feedstock (Sawdust, rice husk, groundnut shell, etc.) is highly crucial. This involves identifying and partnering with reliable suppliers who can consistently provide such high-quality raw materials.

2. Implementing streamlined and optimized manufacturing processes is essential. This includes biomass preparation, compaction, and quality control measures to ensure consistent and high-quality briquette production.

3. Developing efficient logistics and transportation systems is vital for timely and cost-effective delivery of biomass briquettes.

4. Proper storage and inventory management are critical to maintaining an adequate supply of biomass briquettes.

5. Strong collaboration efforts among all stakeholders including fostering open lines of communication, sharing information, and collaborating with suppliers, manufacturers, distributors, and end-users to ensure a coordinated and responsive supply chain.

6. Implementing rigorous quality assurance processes and obtaining necessary certifications ensures that biomass briquettes meet industry standards and customer expectations.

7. Integrating sustainability principles into the supply chain.

8. Embracing a culture of continuous improvement and innovation by regularly evaluating and optimizing supply chain processes, adopting new technologies, and seeking innovative solutions contribute to increased efficiency and competitiveness.

Challenges in Biomass Briquette Supply Chain

According to industry statistics, one of the key challenges is the logistical aspect, where transportation and distribution difficulties contribute to supply chain disruptions. It is estimated that around 30% of biomass briquette production costs are associated with logistics.

Additionally, seasonal availability and unreliable briquette supply chains pose significant hurdles, with biomass feedstocks exhibiting fluctuations throughout the year.

Moreover, studies indicate that moisture-related issues impact the quality and energy content of biomass briquettes, with moisture content reduction being a critical concern during collection, storage, and conversion processes.

Final Thoughts

At Buyofuel, we’re leading the way in transforming the biomass briquette supply chain. Through the power of technology, we bring together all stakeholders involved in the process, from raw material aggregators to biofuel manufacturers and consumers across India. Our innovative platform streamlines the entire supply chain, ensuring seamless coordination and efficient operations.

Whether you’re a supplier, manufacturer, or consumer, we invite you to join our network and revolutionize the biomass briquette industry. For further details, please don’t hesitate to contact us and discover how Buyofuel is making a difference.

Ready to power your business sustainably? Get high-quality biomass briquettes from Gujarat’s leading manufacturer. Contact us now for eco-friendly fuel solutions. Boost your efficiency and reduce carbon footprint today!