Waste is piling up everywhere. According to the peer-reviewed journal Science Advances’ first global plastic analysis, the extreme mass production of plastics from the 1950s to date has generated 8.3 billion metric tonnes of disposable plastics worldwide. And, out of it, 6.3 billion metric tonnes are trash even today. And, the count is increasing every day!

We don’t know what to do with it, and we certainly don’t want to dump it in landfills anymore. Plastic recycling has not yet reached its best potential, and mismanagement is evident. In fact, it has become the biggest problem today since the consequences of using plastics are irreversible. How great would it be to re-utilize these plastics, especially as an alternative to fossil fuel products? There is one such product called waste plastic oil. Let’s find out how it aids.

What is Waste Plastic Oil and How is it Generated?

Plastic oil can be made from recycled plastic, which means that it is a renewable resource. It also burns cleaner than other fuels, which means less pollution will be emitted into the environment.

Waste plastic oil, also known as “plastic waste oil”, is the high-quality oil that is obtained from the processing of waste plastics. The main component of this kind of oil is high-density polyethylene (HDPE) and low-density polyethylene (LDPE).

Waste plastic oil is generated when scrap plastic is collected and sorted for use in manufacturing or recycling via pyrolysis method. During this process, the sorted plastic waste is heated to a high temperature without oxygen, causing it to decompose into a liquid substance (i.e., all the large molecules are broken down into smaller molecules) and then the produced smaller hydrocarbons are further separated to generate fuel via fractional distillation method

Light Diesel Oil (LDO) and Waste Plastic Oil Correlation

Light diesel oil (LDO) is an industrial, non-automotive diesel fuel used in various industrial production unit machinery or engines that require only a low RPM (revolutions per minute) rate. LDO is a commercial extract derived from the distillation of crude oil.

Also, it has a flashpoint of 60 degrees Celsius (lower than heavy fuel oil), which is used mostly as a basic fuel due to its easier ignition nature. LDOs are widely used in boilers, furnaces, lower RPM engines, bunkers, fertilizer plants, and many more to generate heat and electricity.

Waste plastic oil generated from the waste plastics via pyrolysis process is nowadays substituted in the place of LDO boilers in the manufacturing units as most of their efficiency and performance are similar.

Diesel and Waste Plastic Oil Properties and Relationship

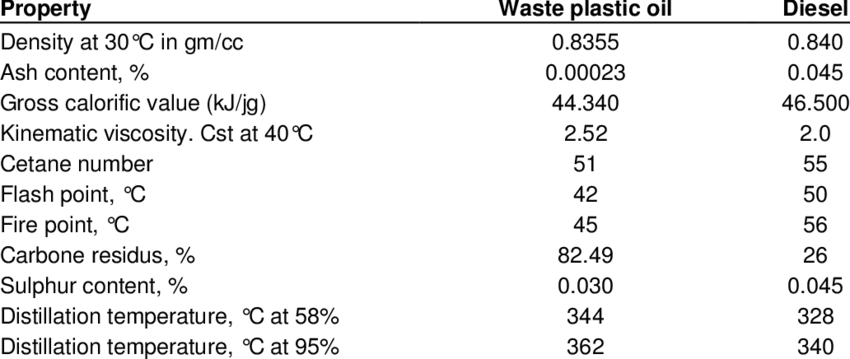

The properties of Diesel and Waste Plastic Oil determine the performance, efficiency and various other factors. For example,

- Calorific value, which describes the heat released by the complete combustion of a unit mass (or volume) of fuel, is a crucial sign of the fuel’s quality.

- Greater the viscosity results in greater fuel consumption, engine load, and engine temperature.

- Oil with a high density might not burn well enough, and oil with a low density might use up more gasoline and harm the engine.

Observe the table given below to analyze the properties of waste plastic oil and diesel:

Waste Plastic oil as a Business Model

To make waste plastic oil a business model, the Dehradun based Indian Institute of Petroleum (IIP), a constituent laboratory of the Council for Scientific and Industrial Research (CSIR), developed a technology to convert plastic waste into fuels in 2014.

This method can turn 1 kg of plastic into 750 ml of fuel suitable for automobiles. IIP’s gasoline made from plastic is pure and complies with Euro-III criteria because there is almost no sulfur present in the fuel produced. A car using this fuel would be able to travel at least an additional two kilometers per liter, according to IIP.

In fact, even today CSIR-IIP technology is making a difference. Recently, it signed an MoU with DDA (Delhi Development Authority) and implemented the advanced pyrolysis plants that convert plastics from MSW (Municipal solid waste). If Delhi succeeds in converting all its waste to diesel, then the advantages will be huge for the city.

Why Haven’t Yet Plastic Waste Oil Caught on?

One significant drawback of plastic oil, as well as other biomass fuels, is that any engine, boiler, or furnace are created with the consideration of the features of fossil fuels in mind.

From a manufacturing perspective, a quick switch to these fuels entails operational risks and other uncertainties that could result in loss for the company. Hence, the hesitation exists. In addition, lack of R&D stimulation and awareness among people affects the growth of plastic oil growth.

Despite its limits, the field is expanding. All as a result of the rapid population growth and industrialization, problems with waste disposal, the depletion of fossil fuels, and stringent carbon emission regulations. Since the Indian government has placed a strong emphasis on alternative fuels, there is little chance that incentives, policy-level involvement, or the stimulation of technology investment will reverse. Undoubtedly, there’s a bright future for plastic oil.

Supportingly, several data show that it is highly possible to use plastic oil derived from plastic wastes as the best alternative fuel for diesel engines as research results are promising.