Source: https://transportgeography.org/contents/chapter4/transportation-and-energy/energy-sources-evolution/

Two centuries later, the difference is we burn biomass in industrial furnaces or boilers instead of in open air. Like your body needs good food to keep you healthy, these biomass boilers need high-quality biomass briquettes to function efficiently.

First, What Are Biomass Briquettes?

Biomass is organic materials from plants and animals. Mostly agricultural waste, organic industrial waste and waste from farms and forestry. When this biomass is mechanically compressed under high pressure and temperature, it’s called biomass briquettes.

Raw Biomass or Biomass Briquettes, Which Is Better?

Naturally, biomass is made of different materials having different characteristics. It is heterogeneous, has different densities, water content, shapes and sizes. The non-uniformity makes it hard to store, transport and use. This results in increased overall costs. And damages the biomass furnace or boiler it is used in.

To overcome these problems, biomass is densified or mechanically compressed into biomass briquettes. They combust well, are efficient and keep the furnaces and boilers in good shape.

What Makes a Biomass Briquette a High-Quality One?

Plain densification of biomass into briquettes is not good enough. Its quality depends on various factors. Here are some of the most important ones:

Moisture Content

The moisture content of biomass briquettes largely depends on the moisture content of the initial raw biomass. The briquettes crack easily if the moisture content is higher than 15%. If the moisture content is too low, the briquettes become fragile and turn into a powder called fines.

The optimum moisture content for high-quality biomass briquettes is ~8%. They produce high-density briquettes that burn longer and generate more heat for you.

Ash Content

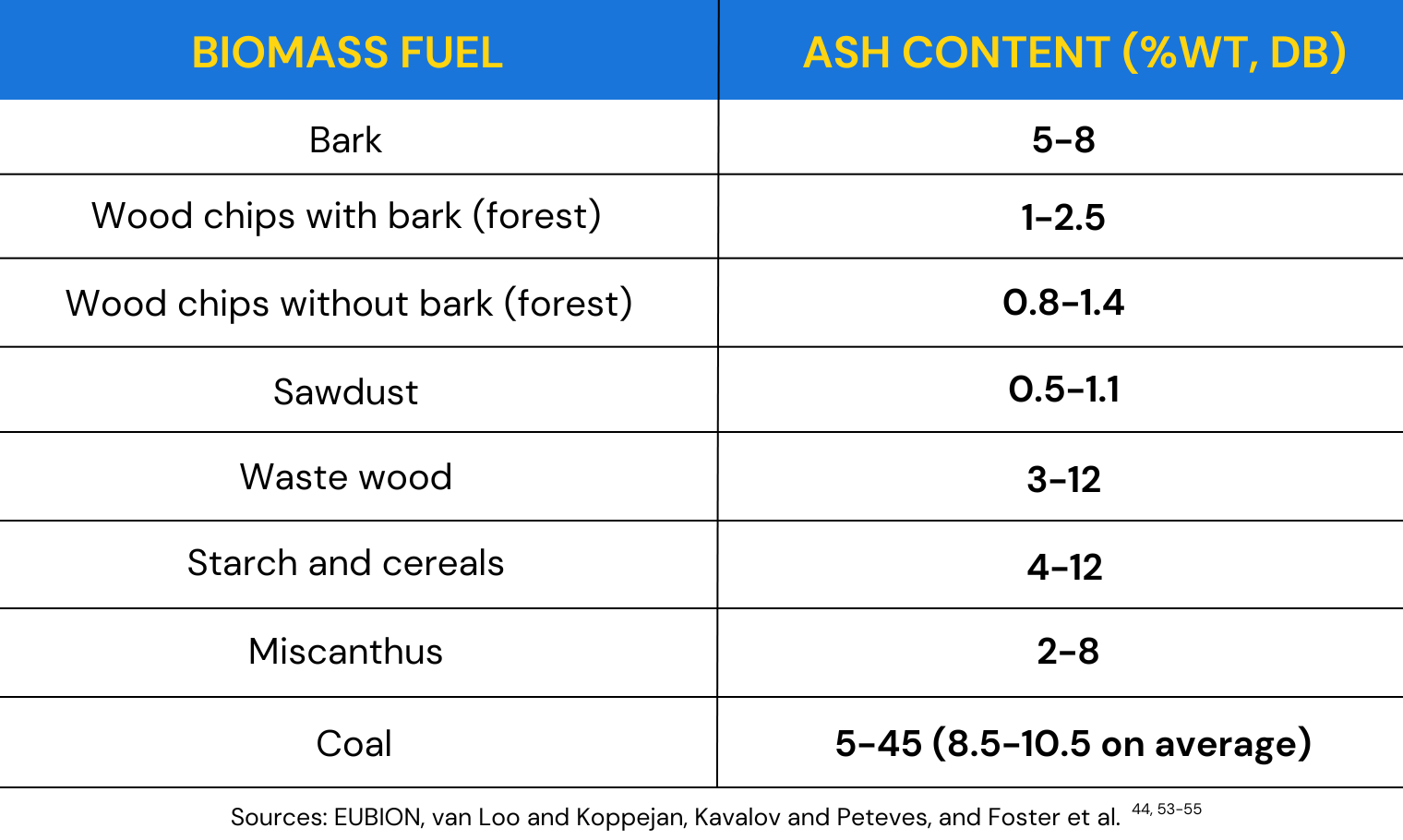

When biomass briquettes are burned in furnaces or boilers, some amount of ash is produced. The left-over ash may block air holes. This lowers the oxygen supply in the combustion chamber. That’s why it’s important to choose biomass briquettes that have the least amount of ash.

Generally, grasses and field crops have higher ash content than wood. This is because they consume more nutrients during growth. When you’re choosing biomass briquettes, remember that the lower the ash content, the higher it’s quality.

Gross Calorific Value

The gross calorific value is also called the value of combustion. It measures the total amount of energy produced when a substance is burned. The calorific value highly influences the quality of biomass briquettes. The higher the value is, the better it will be burnt and more energy it will produce.

Biomass briquettes that have high calorific value are represented by high density and better resistance to humidity. High density indicates that the biomass will burn longer and produce more heat. High resistance to humidity shows that it will stay strong and not crumble when water vapour is released during combustion.

Apart from moisture, ash and calorific value, low sulphur content indicates that the biomass will add less sulphur to the environment, making it safer to use.

In a nutshell, high density, high calorific value, low ash content and optimum moisture content are significant to determine the quality of biomass briquettes. The next time you purchase biomass briquettes in tamilnadu, reach out to us at Buyofuel and we’ll help you keep an eye on these factors.